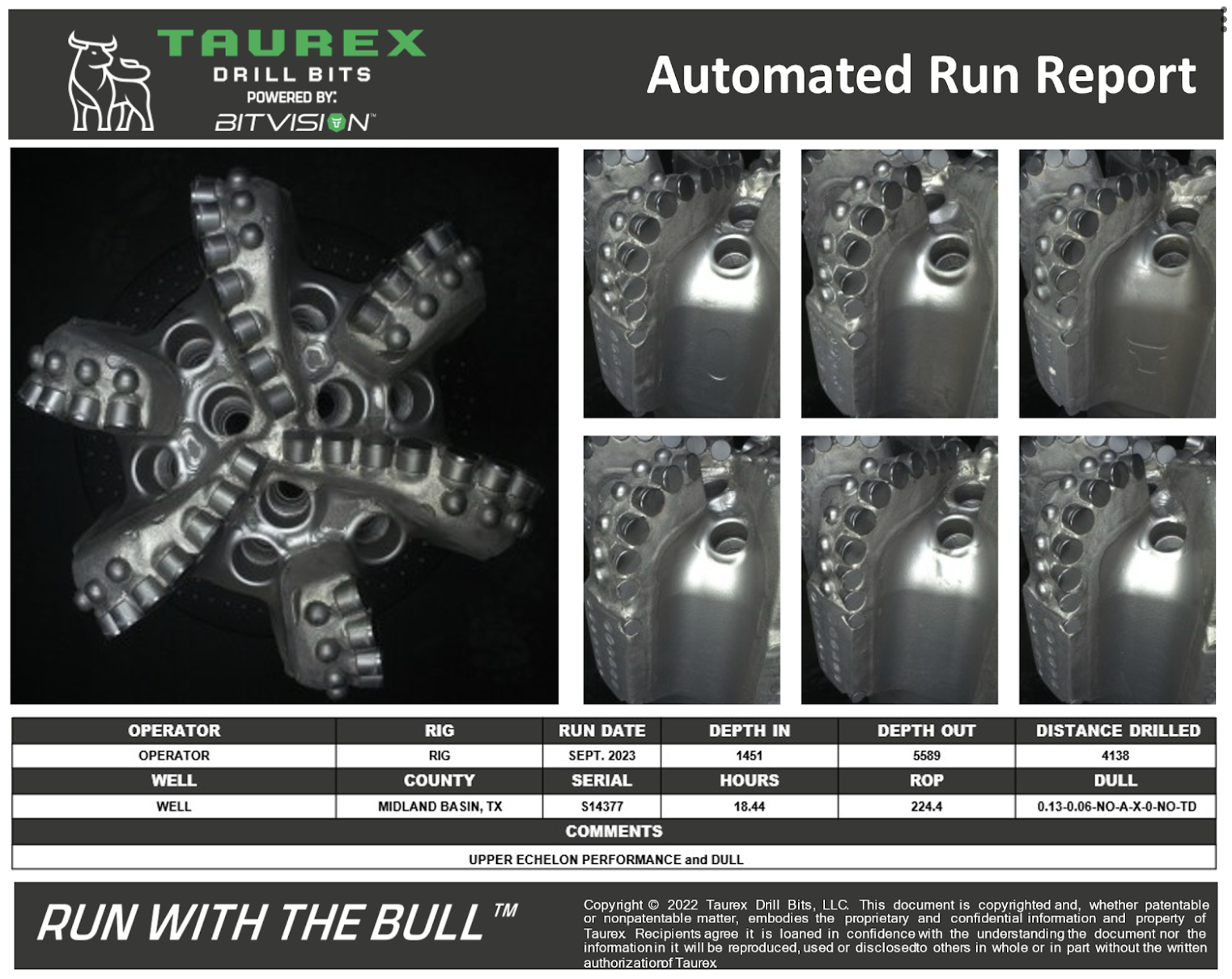

Explore the cutting-edge world of advanced drilling technology with BitVision™, our flagship innovation that embodies the essence of Taurex ingenuity. Incorporating automated photography, scanning, and machine learning models, we are able to generate a digital twin and establish a scalable dataset of precise wear information for each dull drill bit.

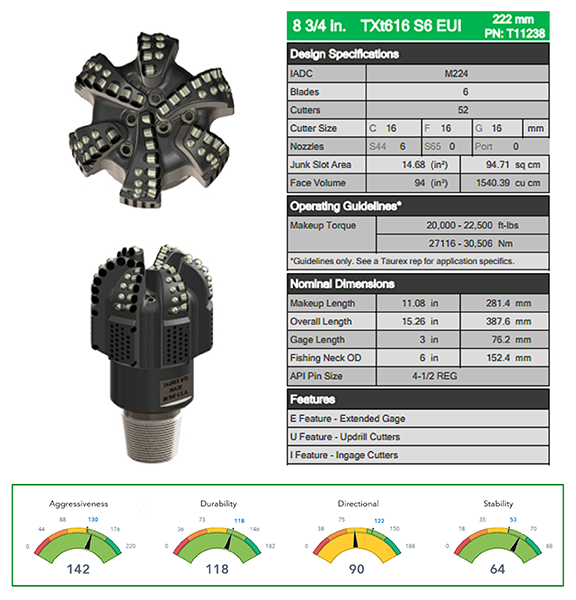

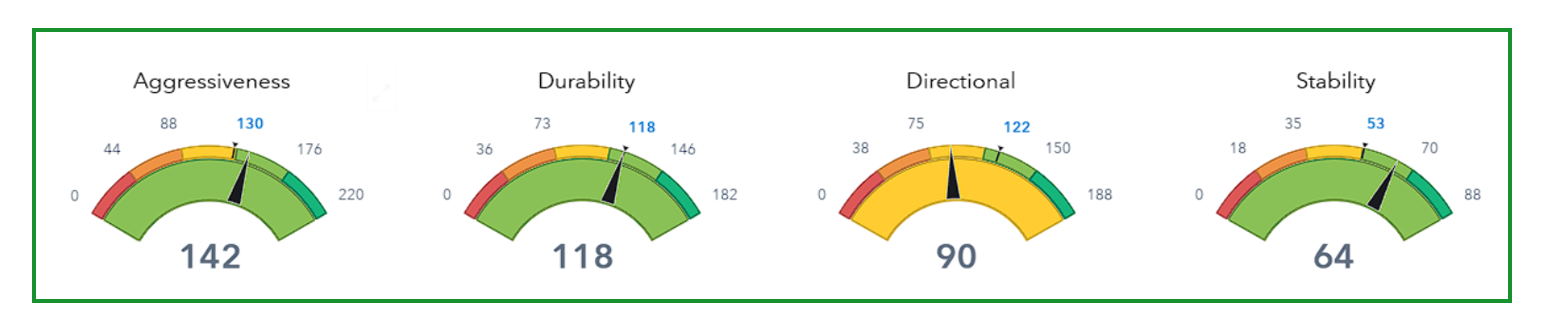

Through our Knowbull platform, clients can access a wealth of drill bit data, providing: Automated scanning reports by part number for all previous run information. High-def photography run recaps by part number for all previous run information. Real-time access to inventory available on rigs by part number. Real-time access to all datasheets for previously run part numbers & available part inventory on rigs. Sort historical and real-time bit data by rig, lease part number, size etc. Inventory that is currently available on rig or lease. Empowering every engineering decision with real-time access to a relational database, our data-driven approach revolutionizes the learning process from every run across all applications – not just a small subset. With the goal of achieving ChatGPT-level proficiency, we boast the world’s largest scan database of dull cutters, utilizing cutting-edge technology that combines scanning, photography, and SME knowledge. PredictaBull distills over 30 complex design variables into key metrics: aggressivity, durability, directional control, and stability. By leveraging historical data and machine learning, it facilitates precise part selection and performance prediction, making it the ultimate solution for informed decision-making in drilling applications. If you would like to know more about our BitVision™ technology, fill out the form, and one of our experts will be in contact with you as soon as possible. Advanced Data Reporting

REAL-TIME ACCESS TO YOUR DATA

Shaping Strategies with Data Insights

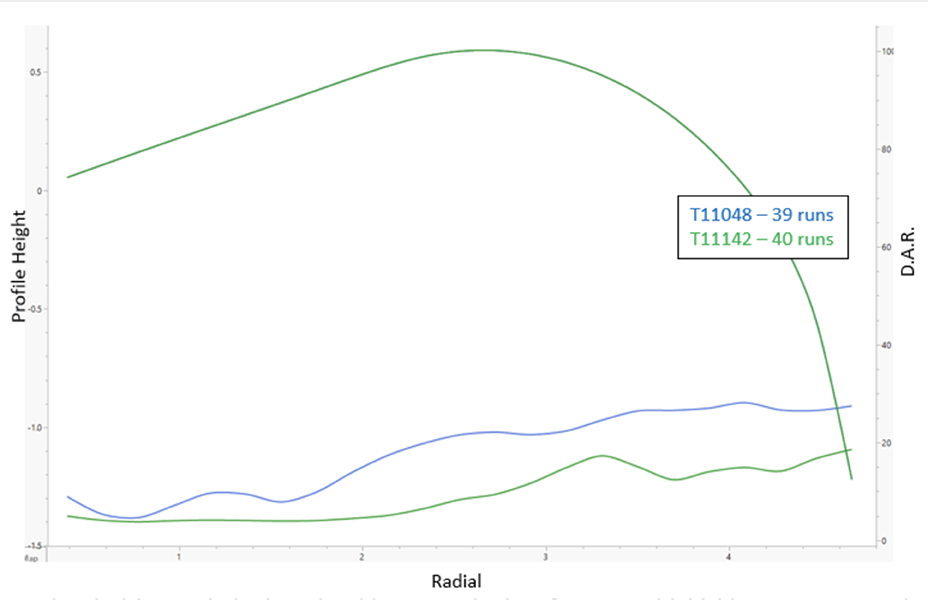

Correlating Design Characteristics to Wear Data

Predict-a-Bull Performance

Interested In Learning More?