Experience cutting-edge PDC cutter engineering with Taurex’s AI-Edge process powered by BitVision™. Utilizing state-of-the-art AI and machine learning, we revolutionize the cutter technology landscape. Our approach, bolstered by comprehensive knowledge capture and automated reporting, empowers engineers and cutter vendors, accelerating innovation and performance advancement.

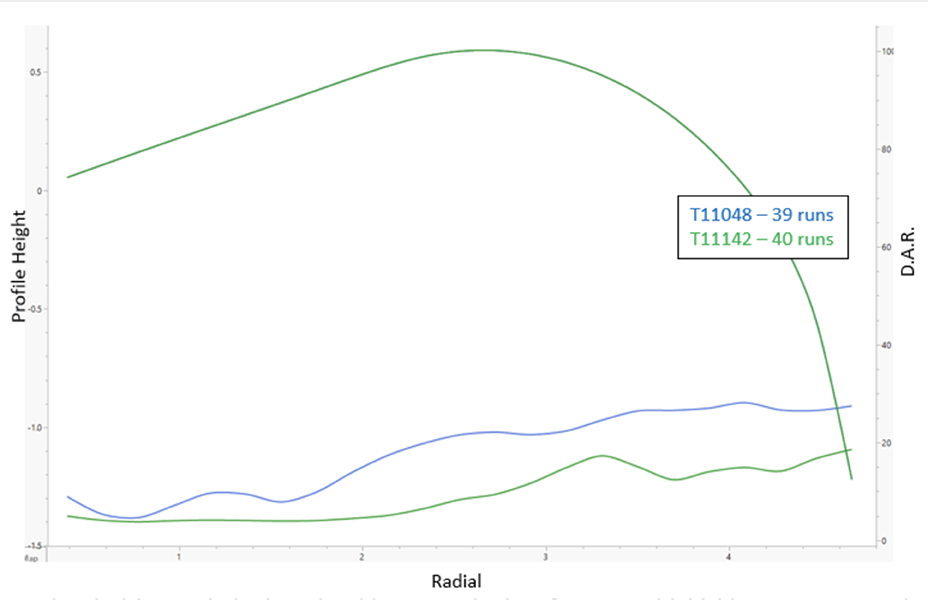

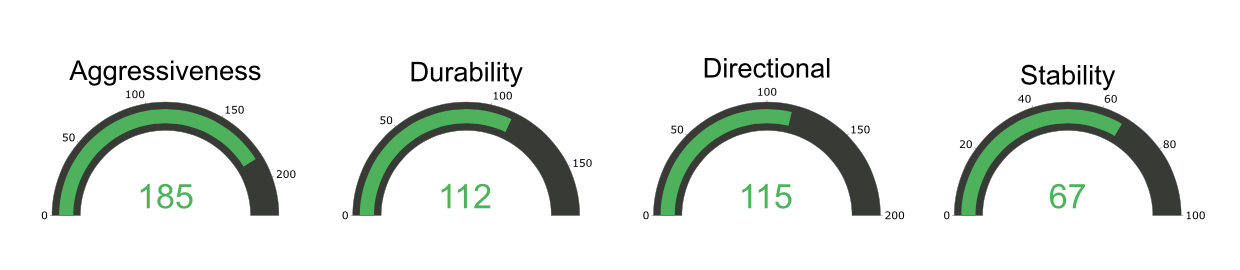

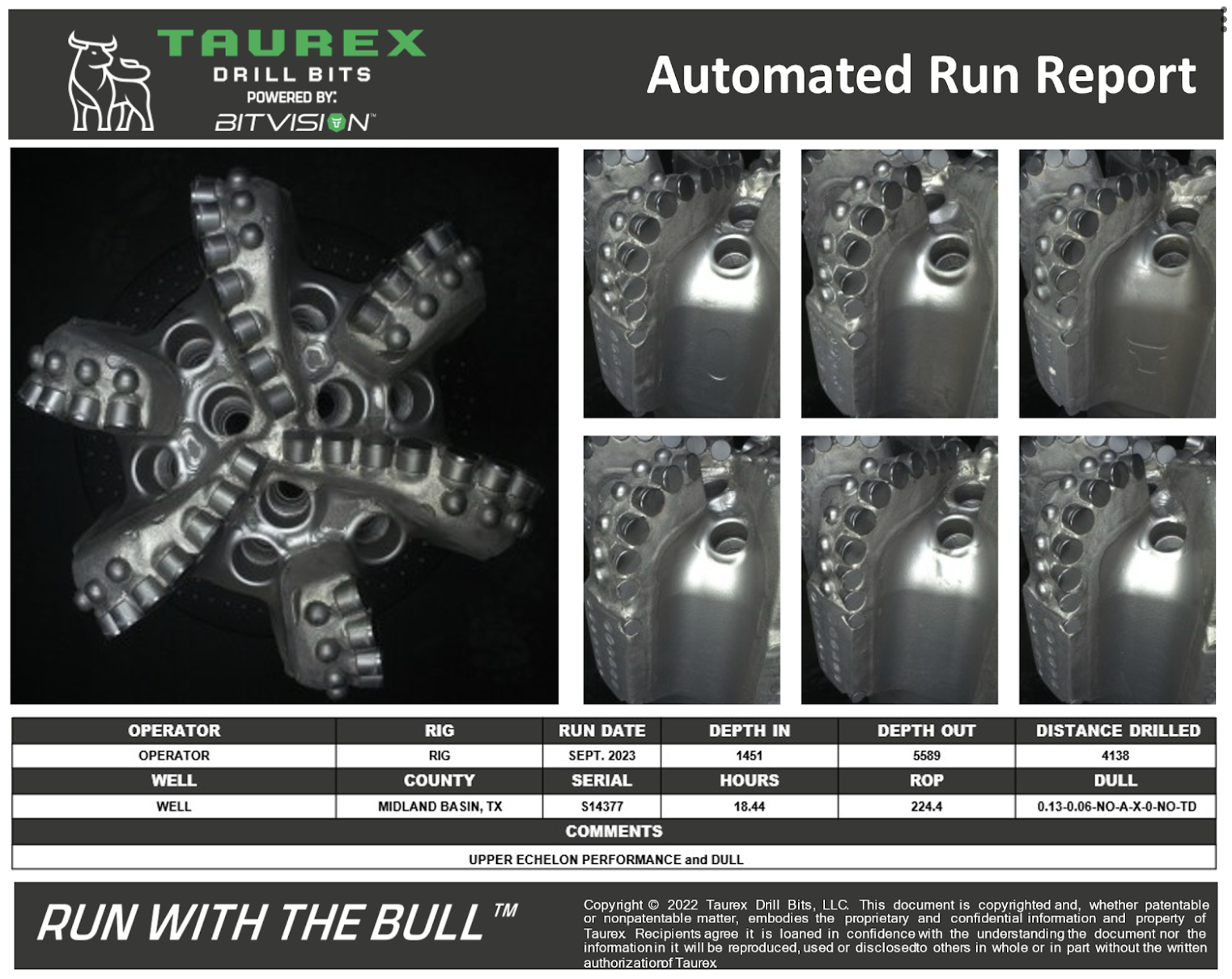

Explore the cutting-edge world of advanced drilling technology with BitVision™, our flagship innovation that embodies the essence of Taurex ingenuity. Incorporating automated photography, scanning, and machine learning models, we are able to generate a digital twin and establish a scalable dataset of precise wear information for each dull drill bit. Through our Knowbull platform, clients can access a wealth of drill bit data, providing: Automated scanning reports by part number for all previous run information. High-def photography run recaps by part number for all previous run information. Real-time access to inventory available on rigs by part number. Real-time access to all datasheets for previously run part numbers & available part inventory on rigs. Sort historical and real-time bit data by rig, lease part number, size etc. Inventory that is currently available on rig or lease. Empowering every engineering decision with real-time access to a relational database, our data-driven approach revolutionizes the learning process from every run across all applications – not just a small subset. With the goal of achieving ChatGPT-level proficiency, we boast the world’s largest scan database of dull cutters, utilizing cutting-edge technology that combines scanning, photography, and SME knowledge. PredictaBull distills over 30 complex design variables into key metrics: aggressivity, durability, directional control, and stability. By leveraging historical data and machine learning, it facilitates precise part selection and performance prediction, making it the ultimate solution for informed decision-making in drilling applications. If you would like to know more about our BitVision™ technology, fill out the form, and one of our experts will be in contact with you as soon as possible. Advanced Data Reporting

REAL-TIME ACCESS TO YOUR DATA

Shaping Strategies with Data Insights

Correlating Design Characteristics to Wear Data

Predict-a-Bull Performance

Interested In Learning More?